MAP25 (Base Model)

MAP25 (Base Model): Standard components, supports different tray and film types.

MAP25 is ideal for small and medium-sized food producers.

Our machines help you achieve increased production while maintaining the highest standards of quality, and with fewer hassles.

Technical Data

| Vacuum Pump: | 35cfm / 60m3/h |

| Air Pressure: | 90 psi / 6 bar (dry) |

| Pressures air consumption: | 0.25 cf/cycle, 1 cf/min / 7 nl/cycle, 30 nl/min |

| Gas Pressure: | 30 – 90 psi / 2 – 6 bar |

| Control Panel: | Touch screen – 24 lines |

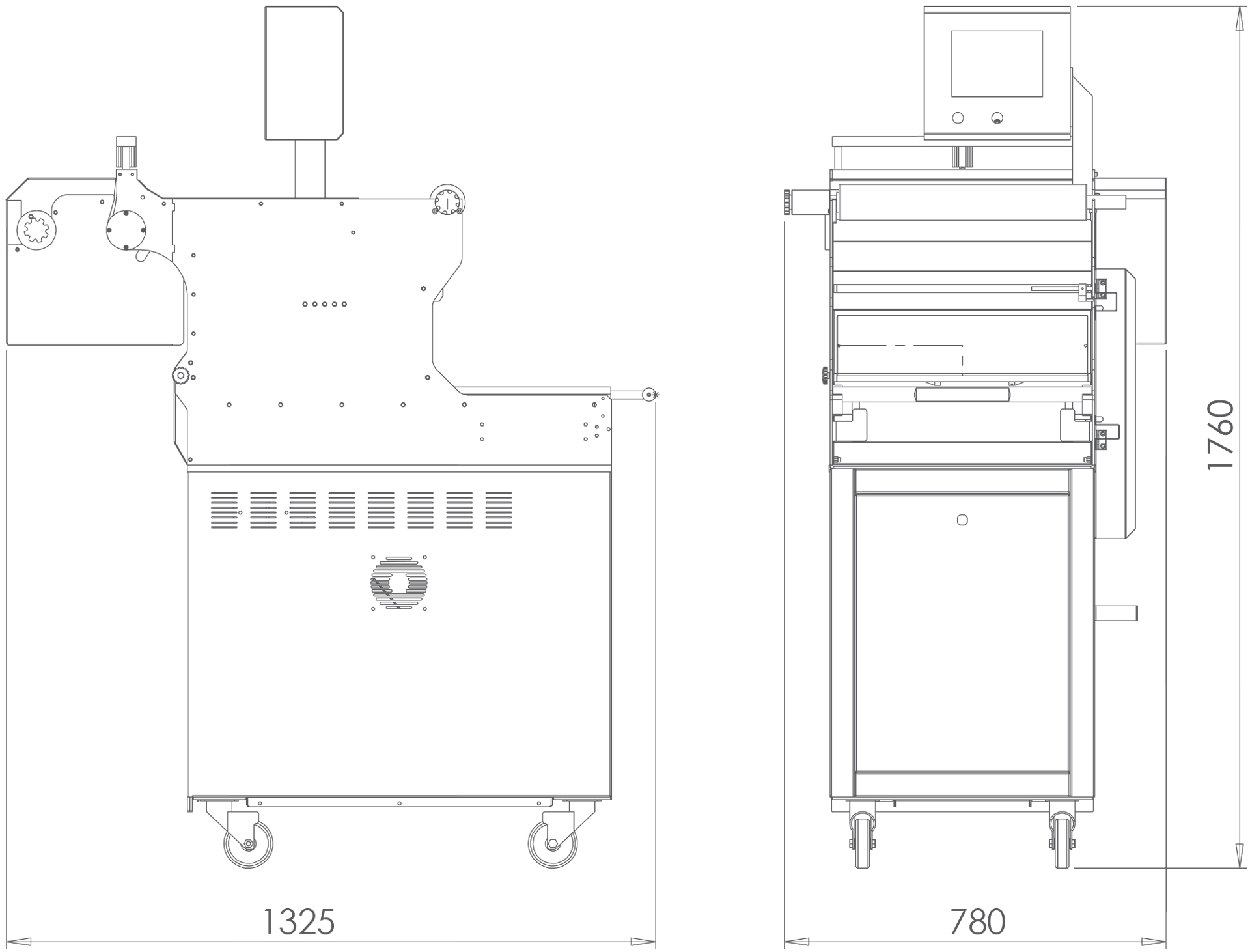

| Dimensions (WxLxH): | 30.70″ x 52.16″ x 69.30″ / 780 mm x 1,325 mm x 1,760 mm |

| Weight: | 995 lbs / 450 kg |

| Film Width: | 18.50″ / 470 mm |

| Capacity: | 2 – 6 cycle/min |

Technical Images

Optimized Solutions for the MAP Packaging Industry

The Semi-Automatic Modified Atmospheric Packaging (MAP) Machines by APACK represent optimized solutions in the food packaging industry, offering an array of solutions designed to meet the growing demand for efficient, reliable, and cost-effective packaging processes. Built on over twenty years of expertise, these machines are engineered to enhance food preservation, extend product shelf life, and reduce operational costs, making them an essential asset for businesses aiming to thrive in a competitive market.

Operational Efficiency: A Core Principle

APACK’s dedication to operational efficiency is evident in the design of its MAP machines. With most models requiring just one operator, businesses can significantly reduce labor costs without compromising on output. The MAP25-DS Double Station model is an exception, designed for higher throughput and necessitating two operators, showcasing APACK’s ability to cater to both small-scale and large-volume packaging needs.

User-Friendly Design for Maximum Productivity

The MAP machines boast an intuitive touchscreen interface that simplifies the packaging process, reducing the potential for user error and increasing productivity. The inclusion of a multi-program memory feature allows operators to switch between packaging setups effortlessly, further enhancing operational efficiency. The machines’ stainless steel construction not only offers durability but also simplifies cleaning and maintenance, ensuring compliance with industry hygiene standards.

Versatility to Meet Diverse Packaging Requirements

Adaptability is a key feature of APACK’s MAP machines, with quick-change molds and sealing tools allowing for the accommodation of a wide variety of tray sizes and configurations. This versatility, combined with the machines’ compact footprint, ensures they can be easily integrated into any food production environment, offering a flexible solution to businesses with diverse packaging needs.

Unwavering Reliability and Support

Constructed from top-quality components, the MAP machines are built to last. APACK’s commitment to customer support ensures that users experience minimal downtime, with a dedicated team ready to address any issues promptly. This reliability and support underscore APACK’s position as a leader in the food packaging industry, offering peace of mind to businesses that depend on uninterrupted production.

Comprehensive Model Range

APACK provides a diverse range of MAP machine models, each tailored to specific packaging demands:

- MAP25 (Base Model): A versatile machine suitable for a variety of tray and film types, ideal for businesses seeking flexibility in their packaging operations.

- MAP25-E (Extended): Designed for larger tray sizes, this model is customized to meet the unique dimensions required by the customer, offering a tailored solution for those with specific packaging needs.

- MAP25-DS (Double Station): Catering to facilities with high production volumes, this model doubles the packaging output, supporting businesses in scaling their operations effectively.

- MAP25-Skin: This model excels in skin packaging, closely molding the top film to the product’s shape and offering adjustable tray heights to enhance presentation and extend shelf life.

- MAP25-X (Custom): For unique requirements, the MAP25-X is designed to handle larger and heavier trays, providing a custom solution that ensures optimal packaging performance.

Innovation and Sustainability in Packaging

Beyond operational benefits, APACK’s MAP machines incorporate features that promote sustainability. By optimizing material use and enhancing product preservation, these machines contribute to reducing waste, aligning with environmental sustainability goals. The efficient use of resources, combined with the extended shelf life of packaged products, demonstrates APACK’s commitment to innovative and eco-friendly packaging solutions.

Customization and Integration Capabilities

Understanding that no two businesses are the same, APACK offers extensive customization options for its MAP machines. This flexibility allows for the machines to be fully integrated into existing production lines, with adjustments available not only in physical dimensions but also in software functionalities. This level of customization ensures that each business can achieve an optimal packaging process tailored to its specific operational needs.

Choosing APACK: A Strategic Decision

Selecting APACK’s Semi-Automatic Modified Atmospheric Packaging Machines is a strategic decision for any business in the food packaging sector. With a range of models designed to meet different operational scales and packaging requirements, these machines offer an efficient, reliable, and adaptable solution. The combination of quality construction, exceptional customer support, and commitment to innovation makes APACK’s MAP machines an invaluable investment for businesses looking to enhance their packaging processes and product quality.

In conclusion, APACK’s Semi-Automatic MAP Machines not only represent a technological advancement in the food packaging industry but also a commitment to operational efficiency, sustainability, and customer satisfaction. By choosing APACK, businesses gain access to a suite of solutions that are tailored to meet their specific packaging challenges, ensuring that they can continue to deliver high-quality products to their customers efficiently and effectively.