Compact, economical design allows the autoMAP100-Mini to fit in processing facilities where space is at a premium

Performs all of the same processes as the larger sized models

Perfect for lower-output facilities working on a budget

Full automation features and online diagnostic access available upon request

APACK autoMAP100 and autoMAP200 series machines provide fully automatic tray sealing and MAP (Modified Atmosphere Packaging) solutions for food production facilities of all different sizes and output volumes.

All of the machines in the APACK autoMAP100 and autoMAP200 series are designed to be customizable, dependable, efficient, and easy to use. Decades of research, development, and industry experience allow APACK to offer you the perfect MAP solution to fit your facility’s unique requirements.

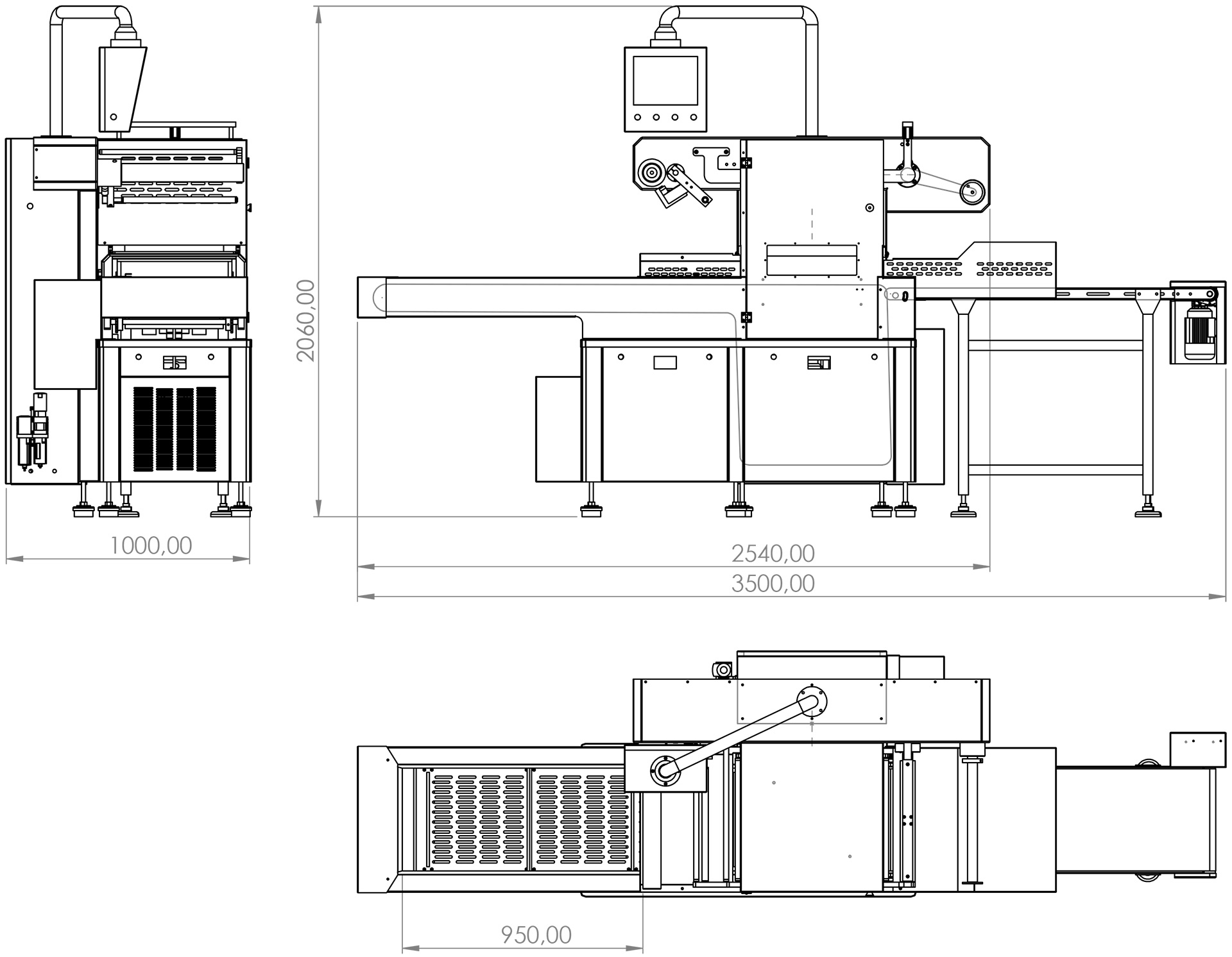

Technical Data

| automap100-Mini | autoMAP100-E | autoMAP200-E | autoMAP MD250 | |

| Vacuum Pump | 105 – 205 | |||

| Compressed Air Pressure | 90 PSI (6 bar) constant and dry | |||

| Gas Pressure | 30 – 90 psi / 2 – 6 bar | |||

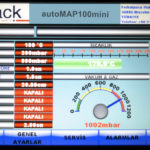

| Control Panel | Touchscreen | |||

| Dimensions (WxLxH) | 990 x 3,350 x 2,050 mm | 990 x 5,200 x 2050 mm | 1,180 x 6,380 x 2,050 mm | 900 x 5,100 x 2,000 mm |

| Loading Area Length | 800 | 1,500 – 3,000 mm | 4,500 – 6,000 mm | |

| Weight | 600 – 800 | 800 – 1200 | 1400 – 1750 | 1,200 kg |

| Max Film Width | 400 mm | 400 mm | 600 mm | 320 mm |

| Max Cut-off Length | 460 mm | 460 mm | 640 mm | 940 mm |

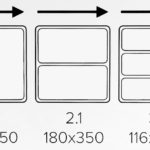

Technical Images

All-in-One, Fully-Automated MAP Solution

Each of the autoMAP100 and autoMAP200 series machines has the ability to carry out fully-automated MAP process and continuous operation

Efficiency and Ease of Use

- Simple, intuitive touch-screen panel makes for fast and easy operation and reduces user error

- Multi-program memory allows for quick transition between different packaging types

- Maintain a safe, sterile food processing environment: stainless steel body, easily removable panels, and hygienically designed conveyor belts and moving parts make frequent cleaning easier

Versatility

- All operation parameters can be adjusted to various tray and film sizes

- Vacuum packing function for easy hermetic sealing of liquids, sauces, dressings, and hot-filled products

- Many customization features are available to fit your facility’s specific needs

Dependability

- PLC control circuits constantly monitor operation to protect equipment against possible faults, misuse, or malfunction

- Invicta’s industry-leading customer service and support means you’ll avoid costly interruptions in production

- Designed and manufactured by APACK – over 20 years at the leading edge of food packaging

- Designed to operate 24/7 under normal conditions with no interruptions

Different Models to Fit Your Needs

The APACK autoMAP100 and autoMAP200 series include four different models, so you can choose one that addresses your needs perfectly.

autoMAP100-E (Extended)

- Accommodates larger package sizes than autoMAP100-Mini

- Higher volume output than autoMAP100-Mini

- Machine dimensions can be customized to fit your packaging and space requirements

autoMAP200-E (Extended)

- Accommodates larger tray sizes than autoMAP100-E

- 2-row production line for double the output of autoMAP100-E

- Design and dimensions of autoMAP200-E is optimized for larger package sizes

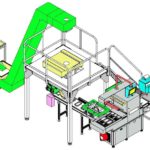

autoMAP MD250

- Designed for high-production facilities with more complex processes and requirements

- Robotic arms transfer the trays in and out of the heat sealing and MAP section

- Machine dimensions can be modified based on facility size, layout, and packaging needs