MAP25-E (Extended): Optimized for larger tray sizes, this model is built to accommodate different dimensions based on the customer’s specific requirements. MAP25-E is ideal for small and medium-sized food producers.

Our machines help you achieve increased production while maintaining the highest standards of quality, and with fewer hassles.

Technical Data

| Vacuum Pump: | 35cfm / 60m3/h |

| Air Pressure: | 90 psi / 6 bar (dry) |

| Pressures air consumption: | 0.25 cf/cycle, 1 cf/min / 7 nl/cycle, 30 nl/min |

| Gas Pressure: | 30 – 90 psi / 2 – 6 bar |

| Control Panel: | Touch screen – 24 lines |

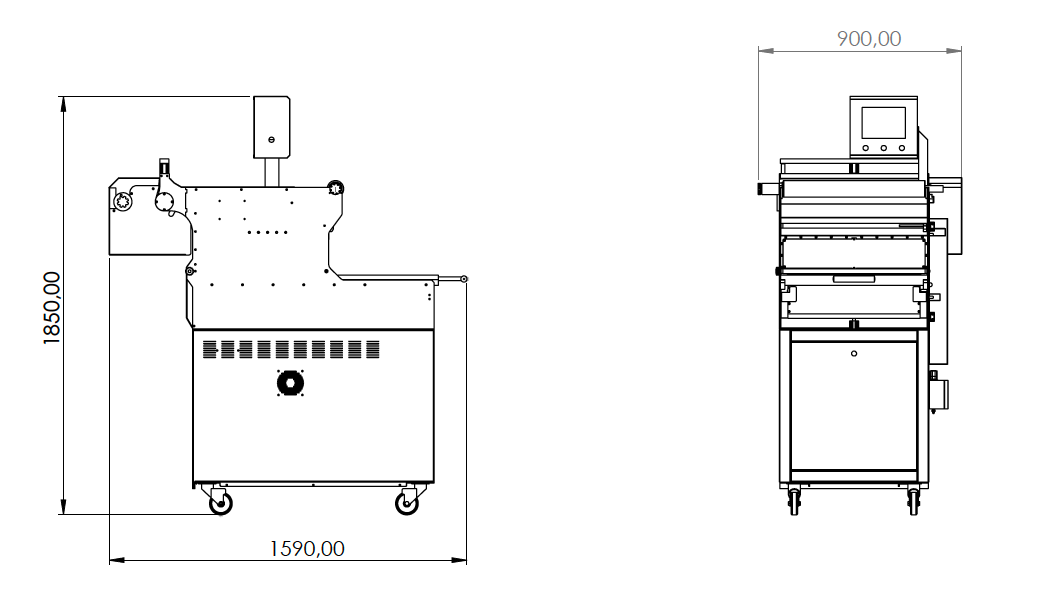

| Dimensions (WxLxH): | 35.43″ x 62.59″, 72.83″ / 900 mm x 1,590 mm x 1850 mm |

| Weight: | 995 lbs / 450 kg |

| Film Width: | 23.62″ / 600 mm |

| Capacity: | 2 – 6 cycle/min |

Technical Images

Low Operation Cost

- Only one operator required (except for MAP25-DS Double Station model – 2 operators required)

Ease of Use

- Intuitive touch screen interface makes operations simple and reduces user error

- Multi-program memory allows operators to quickly and easily switch between different products

- Stainless steel structure is designed to be easy to regularly clean and sanitize

Versatility

- Quick-change molds and tray sealing tools allow MAP25 to be used with a wide variety of different tray sizes and configurations

- Compact design fits easily into virtually any food production facility

Dependability

- Our machines are constructed from the highest quality electrical and mechanical components

- Our industry-leading customer service and support means you’ll avoid costly interruptions in production

- Designed and manufactured by APACK – over 20 years at the leading edge of food packaging

5 Models to Suit Your Company’s Needs

- MAP25 (Base Model): Standard components, supports different tray and film types.

- MAP25-E (Extended): Optimized for larger tray sizes, this model is built to different dimensions based on the customer’s specific requirements.

- MAP25-DS (Double Station): Provides double production capacity for high-output facilities.

- MAP25-Skin: Skin packaging forms the transparent top film to the contours of the food product. The MAP25-Skin can be customized to fit packaging tray heights from 10mm up to 35mm.

- MAP25-X (Custom): Designed to accommodate larger, heavier trays.