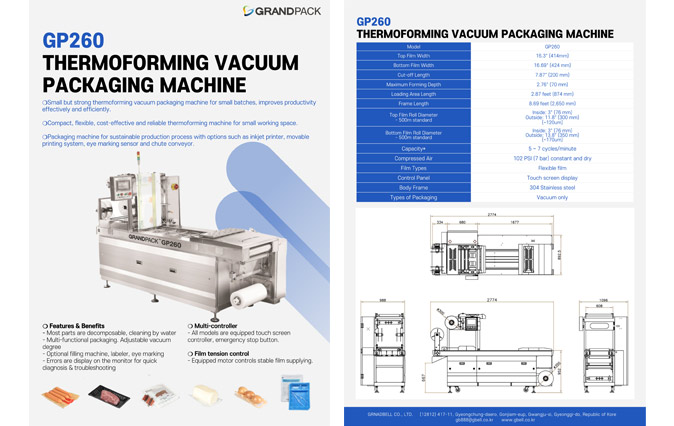

■ Small but strong thermoforming vacuum packaging machine for small batches, improves productivity effectively and efficiently.

■ Compact, flexible, cost-effective and reliable thermoforming machine for small working space.

■ Packaging machine for sustainable production process with options such as inkjet printer, movable printing system, eye marking sensor and chute conveyor.

Technical Data

| Model | GP260 |

| Top Film Width | 16.3″ (414 mm) |

| Bottom Film Width | 16.69″ (424 mm) |

| Cut-off Length | 7.87″ (200 mm) |

| Maximum Forming Depth | 2.76″ (70 mm) |

| Loading Area Length | 2.87 feet (874 mm) |

| Frame Length | 8.69 feet (2,650 mm) |

| Top Film Roll Diameter – 500m standard |

Inside: 3″ (76 mm) Outside: 11.8″ (300 mm) (~120um) |

| Bottom Film Roll Diameter – 500m standard |

Inside: 3″ (76 mm) Outside: 13.8″ (350 mm) (~170um) |

| Capacity* | 5 ~ 7 cycles/minute |

| Compressed Air | 102 PSI (7 bar) constant and dry |

| Film Types | Flexible film |

| Control Panel | Touch screen display |

| Body Frame | 304 Stainless steel |

| Types of Packaging | Vacuum only |

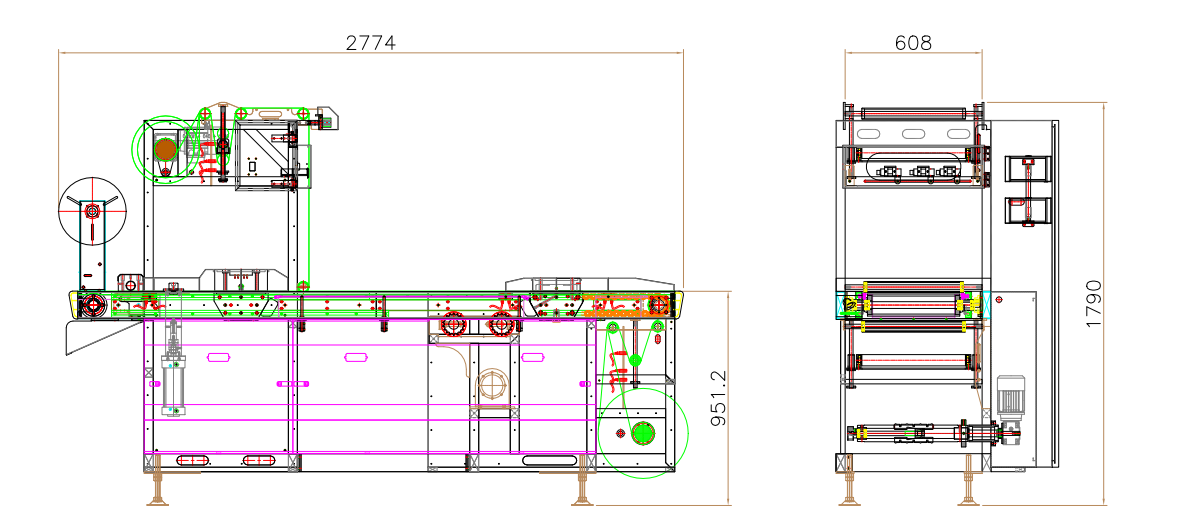

Technical Images

Features & Benefits

- Most parts are decomposable, cleaning by water

- Multi-functional packaging. Adjustable vacuum degree

- Optional filling machine, labeler, eye marking

- Errors are display on the monitor for quick diagnosis & troubleshooting

Multi-controller

- All models are equipped touch screen controller, emergency stop button.

Film tension control

- Equipped motor controls stable film supplying.